- Addr:

- S305, Weiye Building,Pioneer Park, Huoju Hi-tech District, Huli, Xiamen, China 361006

- Email:

- kehao@kehao888.com

Requirements for oven automation control

1. The oven temperature should be able to set upper and lower limit standards;

2. Automatic alarm is required in the following situations:;

2.1. When the furnace temperature just exceeds the upper and lower limits;

2.2. Automatic shutdown of the oven;

2.3. The oven temperature is normal, but the assembly line malfunctions and stops running for 5 minutes;

3. Abnormalities on the recorder can be self indicated;

4. The above alarm prompts must have two types: mobile SMS and visual;

5. When the production line starts running, the furnace temperature generally does not reach the standard value, and there is no alarm within the set waiting time (20-30 minutes);

6. Before and after production, there is no alarm when the furnace is turned on or off;

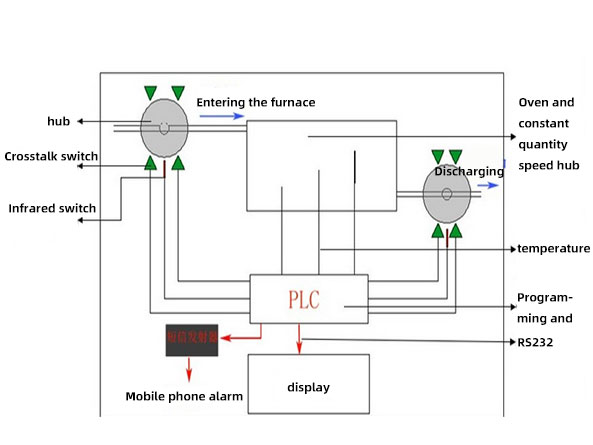

2、 Simple plan

3、 Explanation

1. As shown in the above figure, two sets of photoelectric switches are used to determine whether there is a wheel hub entering the oven on the assembly line. The temperature of the wheel hub before entering the oven is measured using an infrared thermometer (non-contact) and transmitted to the PLC for annotation. Based on the constant speed characteristics of the assembly line, each wheel hub enters the oven at an interval of 14 seconds, and the maximum capacity of the oven and the number of wheels (constant) are calculated. The program is written using the PLC, Align the incoming wheel hub with the outgoing wheel hub, and measure the temperature of the outgoing wheel hub using an infrared thermometer.

If one of the four sets of firing switches exceeds a constant time (such as a 14 second interval between each bracket on the assembly line), a PLC program will be written to output the assembly line fault, and an alarm message will be sent through the SMS transmission platform.

3. Measure the temperature inside the oven, set an alarm value, and send an alarm message if it exceeds the alarm value

Previous article:Not